0SISE Line – Sahara Serrated Squeegee

The Sahara squeegee blade can be safely/efficiently used to apply hot applications. The Sahara Squeegee blade remains stable up to 478° Fahrenheit and has a low reactivity with chemicals. The blade is a hybrid rubber that offers flexibility, malleability, clarity, temperature resistance, and water resistance. In addition, the hybrid blade is resistant to, ozone and UV attacks, and has excellent tensile and tear properties at high temperatures. This squeegee is available as a flat blade or with six different serration depths. Made in the USA.

OSI Line – Sahara Squeegee

The Sahara squeegee blade can be safely/efficiently used to apply hot applications. The Sahara Squeegee blade remains stable up to 478° Fahrenheit and has a low reactivity with chemicals. The blade is a hybrid rubber that offers flexibility, malleability, clarity, temperature resistance, and water resistance. In addition, the hybrid blade is resistant to, ozone and UV attacks, and has excellent tensile and tear properties at high temperatures. This squeegee is available as a flat blade or with six different serration depths.

6700SE Line – Specialty Blend Refill Blade for the 6500SE Line

Haviland’s specialty blend rubber blade makes this squeegee an exceptional value. Available with 1/8, 3/16, 1/4, 5/32, 3/8, and 1/2 inch serrations. Standard serration is 3/16. Indicate serration depth when ordering.

All blades should be stored away from UV light and motorized equipment to maintain the integrity of the blade. Refill blade for 6500SE and 06500SE Lines.

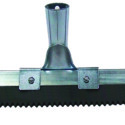

06500SE Line – Specialty Blend Serrated Squeegee

The specialty blend rubber blade has a serrated edge for controlled material deposit. Pliancy of rubber blade allows flexibility of material thickness through pressure and angle applied. Please indicate serration depth when ordering. Serration depths include 1/8, 3/16, 1/4, 5/32, 3/8, and 1/2 inch. Standard serration is 3/16”. Made in the USA.

6500SE Line – Specialty Blend Serrated Squeegee

The specialty blend rubber blade has a serrated edge for controlled material deposit. Pliancy of rubber blade allows flexibility of material thickness through pressure and angle applied. Please indicate serration depth when ordering. Serration depths include 1/8, 3/16, 1/4, 5/32, 3/8, and 1/2 inch. Standard serration is 3/16”. Made in the USA.

- 14 Gauge red powder coated steel frame

- 1/4” x 2” Specialty blend rubber blade

- All steel frame with rounded corners for protection and safety in shipping

- Equipped with a built in scraper

- Steel socket accepts a 1 1/8 tapered handle

- T-66, 66, and PCT-97 sockets are also available

- Refill blade is 6700SE Line

2300NSE Line – Neoprene Applicator Squeegee

The petroleum resistant Neoprene rubber blade has a serrated edge for controlled material deposit. Pliancy of rubber blade allows

flexibility of material thickness through pressure and angle applied. Please indicate serration depth when ordering. Serration depths include 1/8, 3/16, 1/4, 5/32, 3/8, and 1/2 inch. Standard serration is 3/16”. Made in the USA.

02300NSE Line – Neoprene Applicator Squeegee

The petroleum resistant Neoprene rubber blade has a serrated edge for controlled material deposit. Pliancy of rubber blade allows

flexibility of material thickness through pressure and angle applied. Please indicate serration depth when ordering. Serration depths include 1/8, 3/16, 1/4, 5/32, 3/8, and 1/2 inch. Standard serration is 3/16”. Made in the USA.

1400SE Line – Gray EPDM Applicator Squeegee

An efficient method to apply epoxy sealers. The stiffness of the serrated blade provides accuracy for spreading pigment and grit uniformly. The stiffer blade also keeps serration points rigged for increased durability. Please indicate serration depth when ordering. Serration depths include 1/8, 3/16, 1/4, 5/32, 3/8, and 1/2 inch. Standard serration is 3/16”. Made in the USA.

01400SE Line – Gray EPDM Applicator Squeegee

An efficient method to apply epoxy sealers. The stiffness of the serrated blade provides accuracy for spreading pigment and grit uniformly. The stiffer blade also keeps serration points rigged for increased durability. Please indicate serration depth when ordering. Serration depths include 1/8, 3/16, 1/4, 5/32, 3/8, and 1/2 inch. Standard serration is 3/16”. Made in the USA.

2100SE Line – Red EPDM Applicator Squeegee

The EPDM rubber blade has a serrated edge for controlled material deposit. Pliancy of rubber blade allows flexibility of material thickness through pressure and angle applied. Please indicate serration depth when ordering. Serration depths include 1/8, 3/16, 1/4, 5/32, 3/8, and 1/2 inch. Standard serration is 3/16”. Made in the USA.